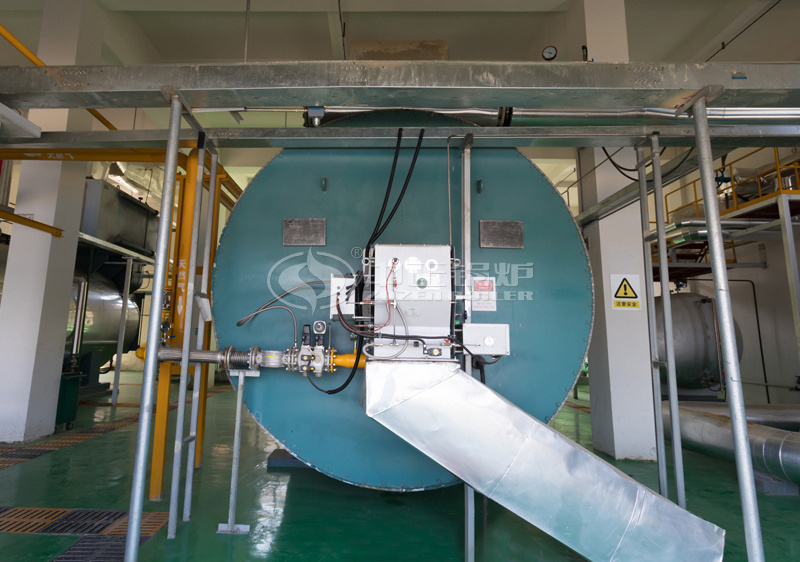

- Mode:

YQW-8200Q

- Capacity:

8.2 MW

- Location:

Ma On Shan, Anhui

Project Description

The new energy automobile cannot develop so rapidly without the strong support of the power battery. The stable heat source provided by the boiler is essentially needed in the production processes of molding, drying and heat treatment. Anhui Xinheng New Material Technology Co. , Ltd. is committed to research and development, production and sales of high-end wet process membranes of lithium ion battery industry. Nowadays, the company has completed the production line of wet process membranes of lithium ion battery with the annual output of 100 million square meters.The tide of green development is sweeping the globe in recent years. As an important part of the new energy industry, Anhui Xinheng New Material Technology Co. , Ltd. sets an example for other enterprises and never slacks in the environmental protection. In the choice of boilers, the company insisted the concept of environmental protection and planned to introduce low NOx boilers and use clean energy natural gas as boiler fuel. ZOZEN tailored technical solutions for the company after learning about their actual requirements: a new set of 7 millions kcal YQW series thermal fluid heater (YQW-8200Q). This series of thermal fluid heaters has the characteristics of high temperature and low pressure, which fully meet the high temperature requirements of the production line. In addition, the tail of the heater is equipped with the energy-efficient equipment such as the waste heat boiler and the economizer to realize the recovery and utilization of waste heat and greatly reduce heat loss, ensuring the thermal efficiency is as high as 95%. Meanwhile, this series of thermal fluid heater is factory packaged and test fired, which will effectively save the installation time and cost of the enterprise.

Client feedback

A thermal fluid heater was a core piece of equipment for the wet process membranes of lithium ion battery industry, the team of ZOZEN was so strong that they tailored technical solutions for us according to the requirements of our production line and completed the boiler installation and commissioning successfully within the scheduled construction period. We purchased another set of WNS series gas-fired steam boiler from ZOZEN in the later period. Both of them were running smoothly now.

— Anhui Xinheng New Material Technology Co. , Ltd.

If you have any questions, please contact our Executive Manager and we will get back to you as soon as possible

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.